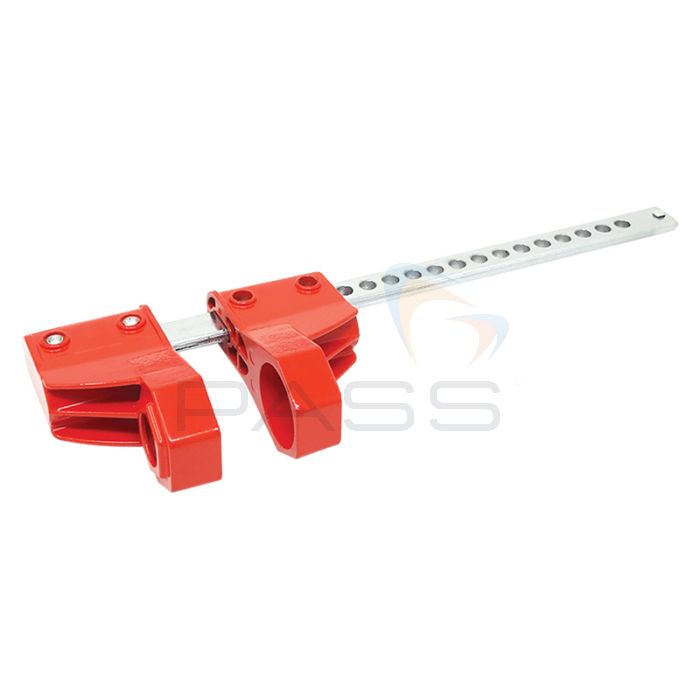

Lockout Lock Blind Flange Lockout - Small, Medium, or Large

These Lockout Lock devices are a physical, best-practice solution for pipeline maintenance. The adjustable cup allows for a secure fit that conceals and locks out access to nuts holding a blind flange in place. Workers can perform maintenance with confidence because they know that the blind they have placed on a pipeline can not be removed until all the workers have removed their padlocks. Available in three sizes, small (½" to 3"), medium (3½" to 12") & large (14" to 24").

- Fully conceals flange bolts preventing access to the blind until all work has been completed

- The adjustable device provides a tight fit, adapting to multiple flanged pipe applications.

- Durable red powder-coated aluminum die-cast construction of the caps and hardened steel customised rod withstand all kinds of site conditions - indoors and outdoors.

- Versatile safety lockout devices secure the flange bolts of ½" to 3" (small), 3½" to 12" (medium) & 14" to 24" (large) diameter pipes

- Eight lockout holes of the hasp, allow multiple workers to lockout the device at one time

Product Range

- Lockout Lock LT-BFL-S Blind Flange Lockout for Pipeline Maintenance - Small

- Lockout Lock LT-BFL-M Blind Flange Lockout for Pipeline Maintenance - Medium

- Lockout Lock LT-BFL-L Blind Flange Lockout for Pipeline Maintenance - Large

Technical Information

Specification

| Small | Medium | Large | |

|---|---|---|---|

| Material | Powder Coated Aluminium die casted & Hardened Steel Rod | ||

| Withstand Temperature | -40℃ - 93.3℃ (-40℉ - 200℉) | ||

| Nut Dia in mm (A) | 19 - 28.7 | 33.3 - 47.8 | 52.3 - 69.9 |

| Nut Dia in inch (A) | ¾” - 1-⅛” | 1-¼” - 1-⅞” | 2” - 2-¾” |

| Pipe Dia Range in mm (B) | 12.7 - 76.2 | 88.9 - 304.8 | 355.6 - 609.6 |

| Pipe Dia Range in inch (B) | ½” - 3” | 3-½” - 12” | 14” - 24” |

Lockout Lock Blind Flange Dimensions

Additional Information

SKU

LT-BFL/S/M/L

Lockout Lock Blind Flange Lockout - Small, Medium, or Large

£72.13

£86.56 inc vat

£72.13

£86.56 inc vat