The Environmental Services Association (ESA) estimates that fires fuelled by erroneously recycled lithium-ion batteries cost UK fire services and waste operators £158 million a year![1] In addition to being economically and environmentally costly, recycling centre fires pose a danger to staff and those in the surrounding areas. However, there is a simple, safe, price-attractive solution to spotting and preventing recycling plant fires before they ignite. FLIR’s A-Series Automation Thermal Cameras identify and alert operatives to hotspots, allowing professionals to take corrective action before sparks form. Discover how FLIR automation thermal cameras can revolutionise your recycling centre fire prevention program.

Quick Links

- The Problem: Recycling Plant Fires

- The Solution: Recycling Plant Thermal Camera Fire Prevention System

- Further Information

The Problem: Recycling Plant Fires

Good faith attempts to repurpose waste have led to an uptick in recycling plant fires. Despite the best efforts of the public and recycling centre staff, errors often lead to flammable items (such as lubricants, paints, grease, oil, and gas tanks) becoming mixed in with recyclables. A particularly pressing problem is the increase in Lithium-ion batteries used in everything from smartphones to toothbrushes to greeting cards. These batteries, though stable while intact, self-ignite when damaged. This is especially dangerous when the Li-ion battery is surrounded by highly flammable recyclable materials, e.g., paper and plastic, or worse, erroneously recycled oil and gas tanks.

Ben Johnson, spokesperson for the Environmental Services Association, explained that in the UK:

“We see around 700 fires every year and at least one serious fire every single day due to batteries that have been improperly discarded.”[2]

~ Ben Johnson, ESA Spokesperson

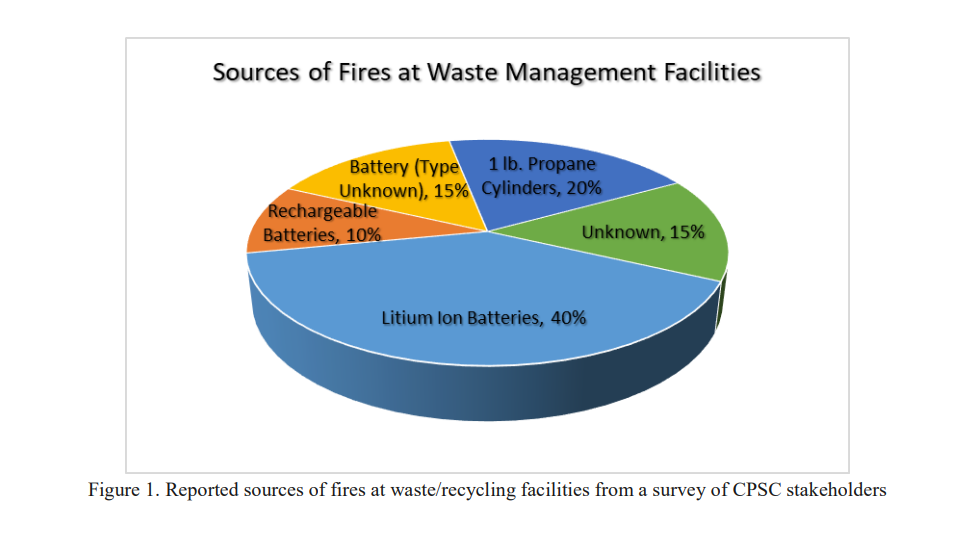

In their January 2021 report, Cutting Lithium-ion Battery Fires in the Waste Industry, produced jointly with Eunomia, the ESA used data from the Environmental Agency to calculate that of the 418 waste fires in 2018/19 [3], 201 or 48% were likely caused by lithium-ion batteries.[4] This trend is mirrored in the USA. A 2018 California Product Stewardship survey found that 40% of fires at state waste management facilities were caused by lithium-ion batteries (batteries of any type caused 65%).[5]

Spotting and removing lithium-ion batteries before they enter the recycling plant, where they may be damaged by sorting equipment, is challenging, especially given the diversity of products using these cells. Nevertheless, lithium-ion batteries are not the only fire hazard facing recycling centres. Heat is a natural by-product of recycling. Hotspots are usually located around machinery or areas where waste products accumulate. If temperatures become too high, this could spark a fire. The risk of fires also increases as more recycling sites open to accommodate rising demand. Furthermore, a hotter, drier climate means fires spread more easily within plants.[6]

The Solution: Recycling Plant Thermal Camera Fire Prevention System

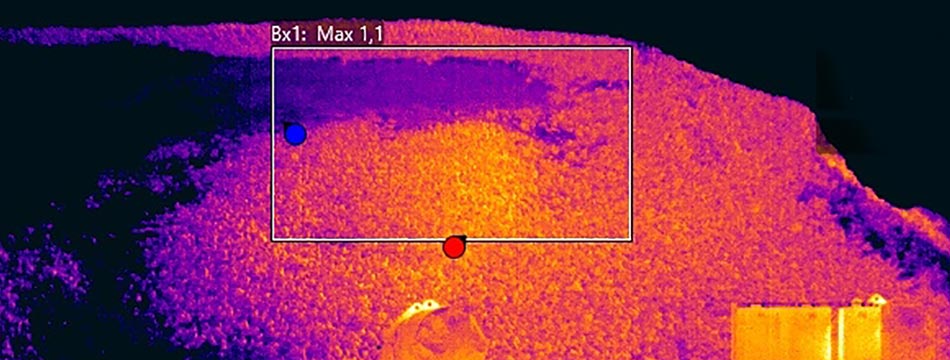

Many recycling centres have already implemented a fire prevention system comprised of smoke detectors and sprinkler/fire suppression systems. However, many also find these systems do not detect fires or alert teams early enough. Automated thermal imaging cameras offer a simple solution. Designed to monitor problem areas for excessive temperatures, recycling operatives can identify hotspots caused by damaged lithium-ion batteries, overheating machinery, or accumulated waste before it has a chance to ignite. As such, corrective action may be taken earlier, thereby minimising danger, damage, and pollution.

Furthermore, as many automated thermal cameras support communication with the Industrial Internet of Things (IIoT), they can be easily integrated into an existing fire prevention system. These thermal cameras may be programmed to issue an alert, via email, text, or call, to relevant persons when a fire is detected and/or temperatures exceed the specified maximum. As a result, teams can take targeted, corrective action sooner, consequently, improving recycling centre safety and productivity. Alternatively, some automated thermal cameras may be programmed to trigger an emergency response, e.g., a smoke alarm or sprinkler system.

Finally, automated thermal cameras can be installed at every stage throughout the waste management process, allowing teams to monitor the entire recycling plant. Remote access to these thermal cameras, via a PC/laptop, smartphone, or tablet (model dependent), means recycling operatives may remain at a safe distance during observation.

FLIR A-Series Automation Thermal Camera Overview

FLIR has developed a series of completely configurable automated thermal cameras specifically designed for fire prevention. The following FLIR A-series models are easily integratable into a waste management or recycling centre fire prevention system.

FLIR A40/A50/A70 Automation Thermal Camera

FLIR A40 Automation Thermal Camera

- IR resolution: 320 x 240px

- Temperature accuracy: ±2°C

- Available with 29°, 51°, and 95° lenses

- On-camera analytics and alarms

- Low-noise imagery and data

- FLIR Atlas SDK

- MSX imaging

- Easy integration into IT systems with support for industrial protocols such as Modbus TCP, EtherNet/IP, MQTT, and REST API

- Diamond-like carbon coating on the lens

- Easy HMI and SCADA integration

- SNMP trap and advanced firewall protection

- Simple configuration via a standard web browser

- Simultaneous VMS video and alarm integration ONVIF S compatibility

- IP66

- Compact and lightweight

- Multiple mounting options

- M8/12 Ethernet, Digital I/O, and RS-232/485 connections

FLIR A50 Automation Thermal Camera

- IR resolution: 464 x 348px

- Temperature range: -20°C to +1000°C

- Accuracy: ±2°C/2%

- Available with an image-streaming or advanced smart sensor configuration

- Available with a selection of lenses

- Built-in analytics

- Onboard alarms

- FLIR Atlas SDK

- Optional MSX imaging

- Optional visual camera

- Integrates into video management systems

- Integrates into HMI and SCADA systems

- Simple configuration via a standard web browser

- SNMP trap

- Advanced firewall protection

- Optional ONVIF S compatibility

- Lightweight

- IP66

- Compatible with an array of mounting options

- Heavy-duty M8/12 connectors

FLIR A70 Automation Thermal Camera

- IR resolution: 640 x 480px

- Temperature range: -20°C to +1000°C

- Accuracy: ±2°C/2%

- Available with an image-streaming or advanced smart sensor configuration

- Available with a selection of lenses

- Built-in analytics

- Onboard alarms

- FLIR Atlas SDK

- MSX imaging

- Optional visual camera

- Integrates into video management systems

- Integrates into HMI and SCADA systems

- Simple configuration via a standard web browser

- SNMP trap

- Advanced firewall protection

- Optional ONVIF S compatibility

- Lightweight

- IP66

- Compatible with an array of mounting options

- Heavy-duty M8/12 connectors

FLIR Axxx Automation Thermal Camera

FLIR A400 Automation Thermal Camera

- IR resolution: 320 x 240px

- Available with an advanced smart sensor or image streaming configuration

- Temperature range: -20°C to +1500°C

- Accuracy: ±2°C/2%

- Compressed radiometric thermal image streaming

- Motorised focus

- Optional FSX technology

- Integrates into monitoring systems

- Compliant with GigE Vision

- Compliant with Genicam

- Supports GigE and RTSP data streaming protocols

- Compatible with third-party SDK and application software support

- Linear temperature output simplifies use with third-party software

- Optional multi-image streaming

FLIR A500 Automation Thermal Camera

- IR resolution: 464 x 348px

- Available with an advanced smart sensor or image streaming configuration

- Edge computing

- IIoT

- Temperature range: -20°C to +1500°C

- Accuracy: ±2°C/2%

- Compressed radiometric thermal image streaming

- Motorised focus

- FSX technology

- Polygon line function

- Adjustable temperature alarms

- Integrates into monitoring systems

- Optional Wi-Fi

- Modbus TCP

- Ethernet/IP

- Integration into HMI/SCADA systems

- Integrates into automation systems using analogue and digital control

- Integrates into REST API over XML or JSON web systems

- MQTT protocol

FLIR A700 Automation Thermal Camera

- IR resolution: 640 x 480px

- Available with an advanced smart sensor or image streaming configuration

- Edge computing

- IIoT

- Temperature range: -20°C to +2000°C

- Accuracy: ±2°C/2%

- Compressed radiometric thermal image streaming

- Motorised focus

- FSX technology

- Polygon line function

- Adjustable temperature alarms

- Integrates into monitoring systems

- Optional Wi-Fi

- Modbus TCP

- Ethernet/IP

- Integration into HMI/SCADA systems

- Integrates into automation systems using analogue and digital control

- Integrates into REST API over XML or JSON web systems

- MQTT protocol

FLIR A500f/A700f Advanced Smart Sensor Thermal Camera

FLIR A500f Advanced Smart Sensor Thermal Camera

- IR resolution: 464 x 348px

- Frame rate: 30Hz

- Digital camera resolution: 1280 x 960px

- Available with a 14°, 24°, or 42° lens

- Temperature analytics

- Edge computing

- Compatible with VMS

- MSX function

- FSX technology

- Polygon, polyline, and line measurement tools

- Compatible with HMI/SCADA using TCP client and server and Ethernet/IP

- ONVIF S compliant

- Integrate into standard security VMS and NVR solutions

- Remote adjustment of the motor focus via Ethernet

- Compressed radiometric streaming to FLIR Atlas SDK

- Durable housing

FLIR A700f Advanced Smart Sensor Thermal Camera

- IR resolution: 640 x 480px

- Frame rate: 30Hz

- Digital camera resolution: 1280 x 960px

- Available with a 14°, 24°, or 42° lens

- Temperature analytics

- Edge computing

- Compatible with VMS

- MSX function

- FSX technology

- Polygon, polyline, and line measurement tools

- Compatible with HMI/SCADA using TCP client and server and Ethernet/IP

- ONVIF S compliant

- Integrate into standard security VMS and NVR solutions

- Remote adjustment of the motor focus via Ethernet

- Compressed radiometric streaming to FLIR Atlas SDK

- Durable housing

Further Information

For more information on using automated thermal cameras, such as FLIR’s A-Series Thermal Cameras, for fire prevention in a recycling centre, please contact our Sales team on 01642 931 329 or via our online form.

In the meantime, you can browse our complete range of automation thermal cameras, including FLIR models, below.

Browse FLIR Automation Thermal Cameras

Shop All Automation Thermal Cameras

[1] BBC News, Batteries linked to hundreds of waste fires, last accessed 01 August 2024 and Eunomia, Lithium-Ion Battery Waste Fires Costing The UK Over £100m A Year, last accessed 01 August 2024.

[2] BBC News, Reading: Battery fire causes £20k damage to recycling centre, last accessed 01 August 2024.

[3] Audra Brown, Mike Brown, Sophie Crossette, Molly Hickman, Mark Hilton, Iona Horton, and Rebecca Mason, Cutting Lithium-ion Battery Fires in the Waste Industry, p6, last accessed 01 August 2024. This figure is likely to be an underestimation as small fires are often not reported to the Environmental Agency, please see page 6 of the report for a full explanation.

[4] Audra Brown, Mike Brown, Sophie Crossette, Molly Hickman, Mark Hilton, Iona Horton, and Rebecca Mason, Cutting Lithium-ion Battery Fires in the Waste Industry, p6. For a detailed explanation of how these percentages were calculated, please see Appendix 1.1, page 69 in the report.

[5] California Product Stewardship Council, Fire Incident Survey 4/9/18, last accessed 01 August 2024 and Ciara Nugent, ‘Why Recycling Plants Keep Catching on Fire’, Time, last accessed 01 August 2024.

[6] Ciara Nugent, ‘Why Recycling Plants Keep Catching on Fire’ and Thermascan, How Thermal Imaging Ensures Safe Waste Management, last accessed 01 August 2024.