International Dangerous Substances and Explosive Atmospheres Regulations dictate that employers are responsible for controlling risks of fire and explosions. This often means investing in intrinsically safe equipment suitable for hazardous areas, sometimes known as explosive locations, or ATEX (Europe) or IECEx (worldwide) zones. However, this is easier said than done. First, you have to know how to identify these zones. Moreover, if you anticipate sharing equipment between international sites, you need to understand how world/European classifications correspond to those used in, for example, North America. That is why we have compiled a simple guide to help you purchase the correct equipment for hazardous areas; so you can protect your staff; maintain regulatory compliance; and avoid dangerous and expensive explosions.[1]

Quick Links

- What Are IECEx/ATEX Zones?

- Why is it Important to Classify Hazardous Areas into ATEX/IECEx Zones?

- How Are Hazardous Areas Classified into IECEx/ATEX Zones?

- Choosing the Right Equipment for Hazardous Areas

- Further Information

What Are IECEx/ATEX Zones?

IECEx/ATEX zones are hazardous areas. This means there is a potentially explosive mix of dust or vapours in the atmosphere and therefore a real risk of explosion if specific conditions occur.

In Gas Atmospheres: Fuel + Oxygen + Ignition Source = Explosion

In Dust Atmospheres: Fuel + Oxygen + Dispersion + Confinement + Ignition Source = Explosion

Examples of ATEX/IECEx Zones

Gas

- Offshore

- Marine (tankers)

- Refining

- Chemical manufacture

- Chemical distribution

- Distilling

- Cosmetics

Dust

- Cement and fine aggregates

- Grain and flour

- Powdered milk

- Sawdust

- Tobacco

- Graphite powder

- Toner

Why is it Important to Classify Hazardous Areas into ATEX/IECEx Zones?

Conservative estimates suggest there is a major hazardous area explosion every 2.9 days![2] Explosions occur when volatile gases or dust in the atmosphere reach ignition temperature. Monitoring machinery in these locations is important to prevent this, ensuring equipment is both functional and working within acceptable temperatures. Overheating machinery may serve as an ignition source, similarly, equipment faults could result in sparks or other incendiary events. Nevertheless, doing this essential monitoring is also risky. This is because equipment introduced to hazardous areas must not contribute to a temperature increase and has to be properly sealed to prevent accidental sparks.

As such, knowing the ATEX/IECEx certification of zones proves extremely useful. First, it helps to communicate key information about the explosive location such as:

- The type of explosive atmosphere present, e.g. gas or dust

- How persistent the atmosphere is, i.e., if it's present constantly, consistently, or inconsistently

Second, understanding the conditions of each area/zone means teams can make informed decisions about suitable test/monitoring equipment and safety procedures. This avoids unnecessary risks and prevents dangerous and expensive explosions caused by unsafe test instruments.

How are Hazardous Areas Classified into IECEx/ATEX Zones?

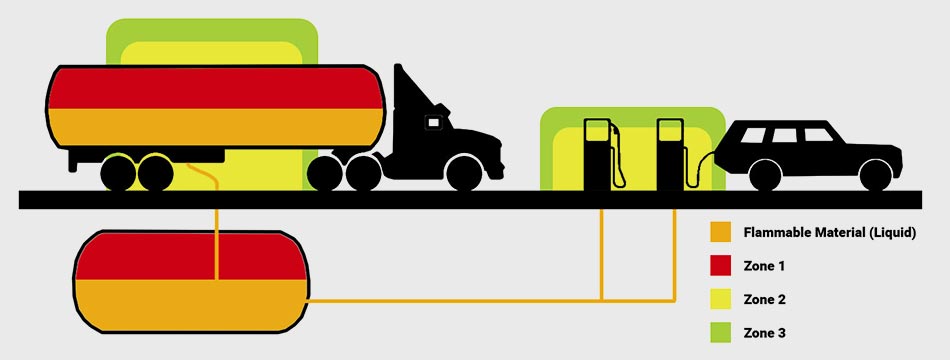

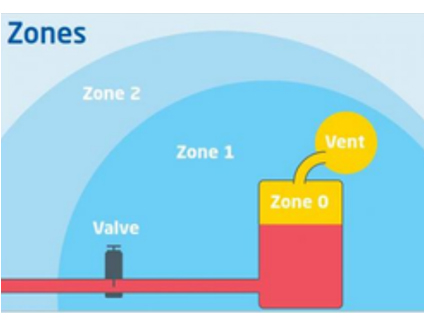

Hazardous areas/explosive locations are classified into ATEX/IECEx zones depending on their risk of explosion and atmospheric type. The potential for an explosion depends on the environment’s construction or application/purpose. See the table below for an overview of ATEX/IECEx classifications.

| Zone | Atmosphere | Definition | Example |

| 0 | Gas | An explosive atmosphere is present continuously or for long periods. | Tanks containing hazardous fuel. |

| 20 | Dust | ||

| 1 | Gas | An explosive atmosphere is present continuously or for long periods. | Around a filling hose during fuel transfer (e.g. petrol station). |

| 21 | Dust | ||

| 2 | Gas | An explosive atmosphere is not likely to occur in normal operation but if it does it will only persist for a short period. | Everywhere else (e.g. outside/beyond the boundaries of a petrol station). |

| 22 | Dust |

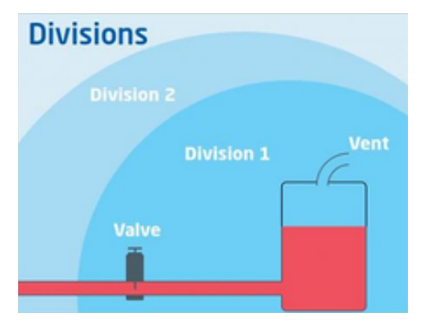

North American Class & Division System

Despite the introduction of ATEX/IECEx classifications, some locations in North America still use their original Class and Division system. Therefore, it is worth understanding this denotation, especially if you or your company intends to use equipment across international sites.[3]

Classes

- Class I: the location is hazardous due to the presence of flammable gases or vapours that may be present in quantities sufficient to create an explosive or ignitable mixture

- Class II: combustible or electrically conductive dust is making the area hazardous

- Class III: the area is hazardous because of easily ignitable fibres in the air; however, these fibres are not suspended in quantities sufficient to produce an ignitable mixture

Divisions

- Division 1: the classified hazard exists,

or is likely to exist, under normal conditions; maintenance work, leakage, or

breakdown could also cause the creation of hazardous conditions - Division 2: the classified hazard does

not normally exist but could manifest under abnormal conditions, for example,

accidental rupture or breakdown

ATEX/IECEx vs North American Classification

Choosing the Right Equipment for Hazardous Areas

Intrinsically safe test equipment is designed for use in hazardous areas/explosive locations. Be that as it may, not all intrinsically safe equipment is suitable for all hazardous areas. Most are certified as safe for use in specific explosive locations, for example, ATEX/IECEx Zone 21 or ATEX/IECEx Zone 22. That’s why it is imperative you know the ATEX/IECEx classification of both the hazardous area AND your chosen instrument. These two classifications must align. For example, if you are working in an ATEX/IECEx Zone 2 hazardous area your chosen test instrument should be ATEX/IECEx Zone 2 certified.

When selecting test equipment for use in hazardous areas, always consider the most dangerous site the instrument is likely to pass through. Then, choose a product certified for use in this explosive location. For instance, if you anticipate using the instrument predominantly in ATEX/IECEx Zone 2 areas but may occasionally need it for ATEX/IECEx Zone 1 sites or even anticipate just crossing through a Zone 1 location, then you need an instrument certified as safe for ATEX/IECE Zone 1 hazardous areas.

Furthermore, if it is likely that test equipment will be used across international sites, you must purchase an instrument that meets both the relevant ATEX/IECEx and international standards. For instance, if your most hazardous North American site is classified as Class I Division 1, then your instrument has to be certified for Class I Division 1 locations.

How Can PASS Help You with Choosing Equipment for Hazardous Areas?

At PASS Ltd we stock an eclectic array of test equipment, including intrinsically safe models by leading manufacturers such as Exloc, FLIR, Fluke, Megger, TPI, and UE Systems. Our intrinsically safe range encompasses digital, thermal, and acoustic cameras, as well as multimeters, thermometers, and pressure modules. Everything you need to maintain the health of your plant!

Browse Intrinsically Safe ATEX Certified Equipment

Moreover, our expertly trained Sales team is on hand to advise on the intrinsically safe equipment suitable for your site and application.

Further Information

For advice regarding ATEX/IECEx or other hazardous area classifications, or for help choosing appropriate intrinsically safe equipment, please contact our Sales team on 01642 931 329 or via our online form.

In the meantime, please browse our extensive range of intrinsically safe equipment by leading brands such as Exloc, FLIR, Fluke, Megger, TPI, and UE Systems.

Browse Intrinsically Safe ATEX Certified Equipment

For further information about working in explosive locations/hazardous areas, please see our following article.

Working in Explosive Locations with the Teledyne FLIR Cx5 Hazardous Area Thermal Camera

[1] Information for this article was gathered from the following sources:

- CSA Group, Definitions for Hazardous Locations, last accessed 15 January 2024.

- Jessica Wright, Working in Explosive Locations with the Teledyne FLIR Cx5 Hazardous Area Thermal Camera, last accessed 15 January 2024.

- Thorne & Derrick, Temperature T-Class Ratings, last accessed 15 January 2024.

- TPI, Do You Know Your Zones?, last accessed 15 January 2024.

[2] Jessica Wright, Working in Explosive Locations with the Teledyne FLIR Cx5 Hazardous Area Thermal Camera.

[3] Following information taken from CSA Group, Definitions for Hazardous Locations.