Acoustic imagers make routine maintenance inspections easy, efficient, and effective. However, where once acoustic imagers were few and far between, now many leading manufacturers offer these inspection tools. More choice is of course better for the consumer; nevertheless, it does present the problem of knowing which model is best for you and your business’ needs. Fluke, who led the charge on acoustic imaging with the ii900 and ii910, has announced three new models, the ii500, ii905, and ii915, that build on the capabilities of their predecessors. When pondering which acoustic imager to choose, consider the following eight reasons for choosing a Fluke ii-series Acoustic Imaging Camera.

Quick Links

- What is an Acoustic Imaging Camera?

- 8 Reasons to Choose a Fluke ii-Series Acoustic Imaging Camera

- Fluke ii-Series Acoustic Imaging Cameras

- Further Information

What is an Acoustic Imaging Camera?

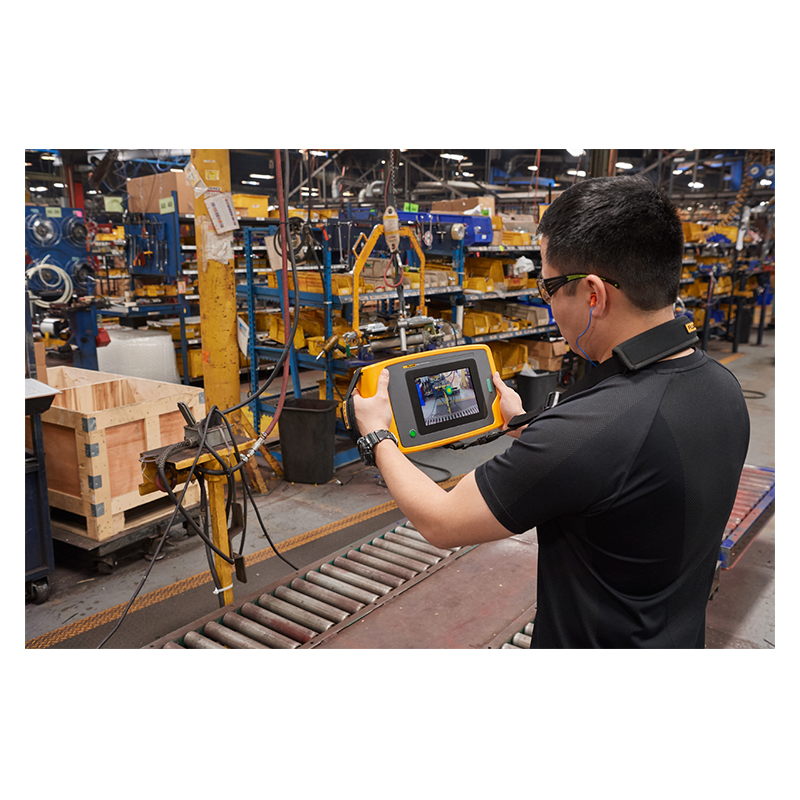

Acoustic cameras, sometimes known as ultrasonic imagers, allow you to see ultrasonic noise. They are ideal for identifying issues such as partial discharge, compressed air/gas leaks, and mechanical faults because they all emit ultrasonic sound. Simple to use, these cameras do not require specialist training to operate, ensuring team members of all experiences can use them.

Acoustic imagers detect ultrasonic sound and convert it into a sound map which is overlaid onto a corresponding digital image. As such, they offer maintenance technicians/engineers an easy method of pinpointing faults precisely and earlier than traditional inspection and diagnostic tools. Addressing issues before they become significant failings reduces health risks as well as repair/maintenance costs. Moreover, advanced filtering technology means ultrasonic cameras can be used during business uptime, minimising expensive downtime usually required for maintenance inspections.

8 Reasons to Choose a Fluke ii-Series Acoustic Imaging Camera

Acoustic imagers eliminate or drastically reduce maintenance, repair, and downtime expenses and make routine inspections quicker and easier. As a pioneer of acoustic imaging, Fluke has developed a range of industry-leading ultrasonic imagers. Here are eight reasons why you should choose a Fluke ii-series Acoustic Imaging Camera.

1.) Get Inspecting Quickly

The Fluke ii-Series Acoustic Cameras’ easy-to-use, fast, intuitive user interface puts everything you need at your fingertips, so you can get inspecting in just five minutes.

2.) Spot Faults Clearly

A high-resolution, capacitive, full-colour, seven-inch touchscreen supports interaction with the intuitive interface. This display provides outstanding viewing, enabling clear detection of partial discharge, compressed air/gas leaks, and mechanical damage.

3.) Capture Images Easily

Optimised for ease and efficiency, the Fluke ii-Series Ultrasonic Imagers have a dedicated button for capturing images. This means you can take photos with just one click and negate time-consuming menu navigation.

4.) Locate, Quantify, & Prioritise Leaks with LeakQ™

LeakQ™ mode is an analytical and reporting tool for estimating the volume and costs of compressed air and gas leaks. The Fluke ii500, ii905, and ii915 offer a variation of the LeakQ™ mode. All will perform automatic scans to capture the frequency range and sound pattern of leaks; then assign the leaks a severity index (scale: 1-10), helping you to prioritise repairs.

ii905 & ii915

The Fluke ii905 and ii915 Acoustic Cameras build on the capabilities of the ii500. In addition to assessing leak severity, the ii905 and ii915 will determine the size, rate, and estimated costs of leaks, allowing you to make informed maintenance decisions backed by data.

5.) Find Mechanical Failings Fast with MecQ™

Only available on the ii915, MecQ™ mode is a first-line inspection tool for identifying mechanical problems early. Consequently, issues can be addressed before they become catastrophic, thereby reducing maintenance/repair bills while maximising uptime.

Predefined and customisable frequency bands, selectable within the MecQ™ mode, enable filtering and trending of dB-level data at any frequency band. Furthermore, contactless scanning and advanced noise filtering ensure maintenance professionals can scan machinery safely even while operations are ongoing. This eliminates expensive downtime usually required for maintenance inspections.

6.) Pinpoint Partial Discharge Precisely with PDQ Mode™

Also exclusive to the ii915 Acoustic Camera, the PDQ Mode™ helps high-voltage (HV) engineers visualise what was once invisible. It converts ultrasonic sound emitted by partial discharge (PD) into a sound map which is superimposed on top of a corresponding digital image. As a result, HV professionals can pinpoint sources of partial discharge.

PDQ mode™, combined with an extended 2-100 kHz frequency range, facilitates early detection of partial discharge, empowering high-voltage teams to address PD problems before they result in arc flash fires, blackouts, explosions, and other dangers to life. In addition to protecting life, correcting PD problems early can reduce repair bills significantly and eliminate unplanned downtime. To help high-voltage professionals correct these problems and make informed maintenance plans, PDQ mode™ will classify partial discharge and assess its severity.

Moreover, as with the MecQ™ mode, this function allows HV engineers to conduct inspections from a safe distance and during plant uptime. Once again, this eradicates expensive inspection downtime.

7.) Manage Assets Seamlessly

Tagging and annotation features, such as photo notes, asset identifiers, text notes, and QR codes, ensure teams can manage assets and maintenance progress seamlessly. QR codes can be used to identify inspections while priority and follow-up actions may be added in notes. Flawless integration with FlukeConnect™ desktop software ensures all team members are kept up-to-date with the latest actions.

8.) Maximise Uptime

In addition to facilitating inspections during uptime and helping to eliminate unplanned downtime by catching issues early, the Fluke ii-series Acoustic Cameras are powered by a battery pack capable of providing six hours of operating time. This means they can comfortably deliver a full day’s inspecting.

Download Fluke’s ii500, ii905, & ii915 Brochure

Fluke ii-Series Acoustic Imaging Cameras

There are three models in Fluke’s latest series of ii Acoustic Imaging Cameras: the ii500, ii905, and ii915.

Fluke ii500 Acoustic Imaging Camera

- Entry model

- For locating gas and vacuum leaks

- Advanced acoustic leak detection technology

- Isolates leak sound frequencies and filters out background noise

- Frequency range: 2-52 kHz

- Detection range: 50m

- SoundMap™ technology

- 0.3MP digital camera

- LeakQ™ severity index (1-10)

- Locate leaks during uptime

- 7", 1280 x 800px LCD screen

- Capacitive touchscreen

- Annotate, tag, and save images and videos

- 20GB memory

- Reporting Tool

- Easy to use

- Minimal training required

- Scan large areas

- Scan smaller components such as hoses, fittings, and connections

- Perfect for pinpointing air, gas, steam, and vacuum leaks

Fluke ii905 Acoustic Imaging Camera

- Mid-range model

- For detecting and assessing compressed air, gas, steam, and vacuum leaks

- Scan air systems, pipelines, and industrial equipment for leaks

- Advanced leak detection technology

- Isolates leak sound frequencies and filters out background noise

- Frequency range: 2-65 kHz

- Detection range: 70m

- SoundMap™ technology

- 5MP digital camera

- LeakQ™ Assessment (size, rate, cost, and severity)

- Locate leaks during uptime

- 7", 1280 x 800px LCD screen

- Capacitive touchscreen

- Annotate, tag, and save images and videos

- 32GB memory

- Save images and footage to folders

- Share images and footage with relevant persons

- Reporting Tool

- Wi-Fi interface

- Easy to use

- Minimal training required

- Perfect for pinpointing air, gas, steam, and vacuum leaks

Fluke ii915 Acoustic Imaging Camera

- Flagship Model

- Detect leaks, find mechanical faults, and pinpoint partial discharge

- Advanced leak detection technology

- Isolates leak sound frequencies and filters out background noise

- Frequency range: 2-100 kHz

- Detection range: 120m

- SoundMap™ technology

- 5MP digital camera

- LeakQ™ Assessment (size, rate, cost, and severity)

- MecQ™ mode

- PDQ mode™

- Locate leaks during uptime

- 7", 1280 x 800px LCD screen

- Capacitive touchscreen

- Annotate, tag, and save images and videos

- 32GB memory

- Save images and footage to folders

- Share images and footage with relevant persons

- Reporting Tool

- Wi-Fi interface

- Easy to use

- Minimal training required

- Scan large areas, compressed air systems, industrial equipment, insulators, transformers, and high-voltage power lines

Further Information

For additional information regarding Fluke’s ii-Series Acoustic Cameras, please contact our Sales team on 01642 931 329 or via our online form.

In the meantime, you can browse our complete range of acoustic imagers, including Fluke Acoustic Cameras, on our website.

Further details regarding Fluke’s latest ii-Series Acoustic Imaging Cameras can also be found in their brochure, available here.