Test equipment calibration is one of the most important parts of using test equipment. It's a question we get asked often - just what exactly is calibration anyway?

I find it's often best to explain calibration like it's a car's MOT test. Think of the principles behind an MOT test; you're basically getting your car checked to see if it is working with accepted specifications and is road-safe. With calibration, the same principle applies - you're checking your test equipment to make sure it works to the correct specifications, ensuring you get the results you expect.

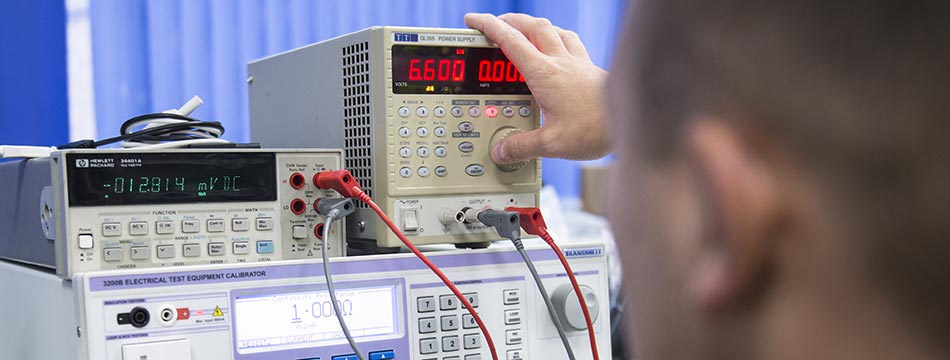

That's the easy way to explain it. If you want to get more technical, calibration is the process where an accredited calibration house (such as our own lab - more info available at www.calibrate.co.uk) checks that your equipment is working as it should be, in line with recognised standards which the calibration house works to. The calibration provider checks that your equipment is still accurate, if there's any drift (which is when a piece of testing equipment begins to work incorrectly), they can source the cause, adjust and make repairs as needed to get the tester working to full capacity.

This again ties in with the idea of an MOT test for test equipment. The calibration house checks everything out to a set of pre-established standards, flags up any issues, then gets to work repairing it so you can start working again.

How Often Do I Need to Calibrate My Equipment?

Test equipment should be calibrated every year.

Regardless of the type of tester, how often it has been used that year or other factors, calibration is an essential. A tester's operation can be affected by so many different factors; whether it's an electrical surge damaging components, or moisture intrusion after it's been left in a cupboard, the accuracy of your tester can easily be compromised over the year.

Whenever your calibration is due, your provider should send you a reminder that you need your unit calibrating. You can then organise delivering it to the lab, where technicians will check its accuracy and make repairs as needed to ensure accurate calibration.

What is a Calibration Certificate?

Test equipment should be calibrated on an annual basis, regardless of how much it has been used during that time period. Calibration cannot be performed yourself; although calibration units are available on the market, only those with an accredited status as a calibration laboratory are able to give out calibration certificates, which is your proof that the unit has been calibrated.

Calibration units which are commercially available are generally used to check the ongoing accuracy during the year between official calibration; however, they cannot be used as proof that your tester is calibrated, as you don't have the certificate to prove it.

Are New Testers Calibrated?

In short, yes. However, not all manufacturers provide a calibration certificate to prove this.

If you don't have a calibration certificate for your tester, you may be refused work and may come into issues if something goes wrong. Your calibration certificate is your proof that your tester is working within standard; without it, you have no way of knowing whether the results you are generating are in any way accurate.

On test equipment that we provide, we give customers the option to add a calibration certificate to their order. When this is ordered, we will calibrate the new tester in our lab and supply a certificate alongside it which is valid for a 12 month period.