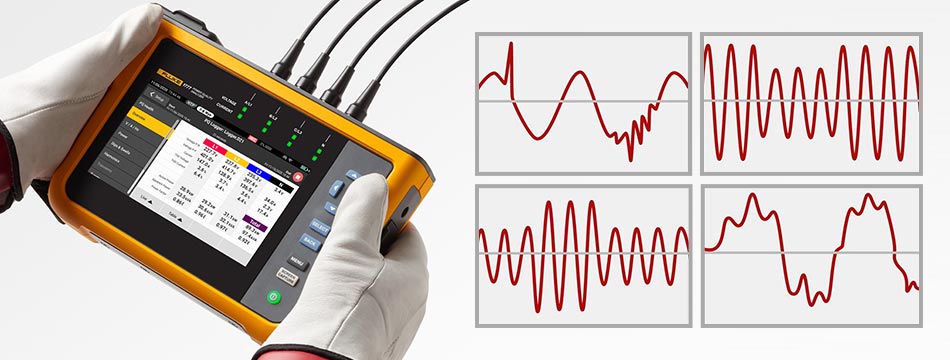

Power quality problems aren’t always immediately recognisable. Without power quality monitoring, issues within electrical distribution systems and/or faults with equipment may be misdiagnosed as, for example, an old breaker that needs to be replaced. Misdiagnosis could lead to ineffective 'corrections', for instance, resetting the equipment or circuit. Spotting the signs of power quality issues early is essential to prevent further damage to systems or equipment. Once symptoms have been recognised, you can use a power quality analyser, such as Fluke’s 1770-Series Power Loggers, to monitor loads, voltage, current, harmonics, and unbalance or disturbance patterns.[1]

Quick Links

Signs and Symptoms of Power Quality Issues

Power quality issues tend to result from harmonic distortion or voltage and current anomalies; thankfully these faults can be easily corrected before they become harmful

Common power quality faults such as dips or sags, swells, transients, interruptions, unbalance, and harmonics are frequently characterised by specific symptoms and may point towards particular causes. Below are just some of the signs you should look out for.

Dips or Sags

Dips and sags are normally caused by starting large inductive loads or similar operations in neighbouring facilities; they can also be triggered by severe weather. Spurious/unexplained alarms and shutdowns, computer lockups, dimming lighting, and relay and contactor chatter or dropout are all indicative of dips and sags.

Swells

Faults on a single phase of a three-phase system, a sudden load decrease, or capacitor bank switching can cause swells. Failed power supplies, overvoltage shutdowns, and alarms on variable frequency drives (VFDs) are signs that point towards this fault.

Transients

Damaged insulation, failed electronics, computer lockups, and flashover and arcing effects in distribution equipment suggest an issue with the system’s transients. This type of fault is often caused by lightning strikes, switching capacitors, and dirty/worn contactors. Transient issues can also result from suddenly stopping large equipment or re-energising systems after a power failure.

Interruptions

Interruptions are characterised by equipment shutdowns and are caused by a momentary loss of utility power.

Unbalance

Overheated three-phase motors and transformers are a symptom of unbalance. This fault usually results from unbalanced loads across individual phases of three-phase panel boards, an unbalanced utility supply, open-delta transformers, or the operation of single-phase welders.

Harmonics

Arc furnaces, welders, non-linear loads (e.g., switching power supplies) or converter sections of uninterruptible power supplies (UPS), variable frequency drives (VFD), and battery chargers can all cause harmonics issues. To spot this type of fault, look out for overheated neutral conductors, transformers, or inductive motors, and/or spurious/unexplained alarms or equipment shutdowns.

Further Information

For more information about how to spot power quality issues and/or details about the Fluke 1770-Series Power Quality Analysers which can be used to monitor and diagnose all the above faults, please contact our Sales team on 01642 931 329 or via our online form.

In the meantime, please browse our extensive selection of power quality analysers, including models by Fluke.

[1] Information for this blog was gathered using the following source:

- Fluke, Quick guide to power quality symptoms and causes, last accessed 23 February 2022