An Electrical Training Trust (ETT) survey of Northern Irish electrical professionals uncovered that 80% of respondents had suffered an electric shock at work, with approximately 40% experiencing over three incidents. Of this 80%, nearly all (95%) have had to take time off work and 89% sustained an injury. Nevertheless, 97% of those surveyed believed they had a ‘good awareness’ of electric shock risks. However, a disregard for safety procedures, such as safe isolation, was found to be a leading cause of accidents among professionals, proving the value of these precautions. Consequently, the ETT suggests emphasising the importance of safe isolation procedures; standardising safe isolation training; and ensuring easy, affordable access to appropriate safe isolation tools as actions that can be taken to improve electrical safety.[1]

Quick Links

ETT Report: Ending Shock Silence

ETT’s Ending Shock Silence report originates from another ETT campaign, ‘Save Our Sparks’. This 2023 campaign centred around ‘Michael’s Story’. Michael Adamson was a 26-year-old electrician who died because of a preventable workplace accident. It aimed to raise awareness of the importance of safe isolation. As part of this campaign, ETT ran a safe isolation survey which uncovered some disturbing findings, including:

- Over 30% of respondents rarely or never use a

lockout kit to isolate the electrical supply they are working on - 1 in 60 of those surveyed don’t use any test

equipment to verify there is no charge - 50 respondents reckoned that they were

experienced enough not to make any mistakes and therefore didn’t feel the need

to isolate or test the circuit they were working on

In addition, ETT noted a lack of information about electric shocks; the reporting of shocks; and the immediate and long-term effects of these incidents. Consequently, in 2024 ETT launched an Electric Shock Survey. The purpose of the survey was to garner insights and feedback from electrical workers in Northern Ireland related to safety procedures and practices, specifically:

- Frequency of electric shocks

- Physical and mental impacts of electric shocks

- The culture surrounding the reporting of electric shocks

- Actions taken by employers and workers to prevent electric shocks

- Ways to improve awareness and understanding of the risks and dangers of electric shocks

Why is the Electric Shock Survey Important?

The transition to net zero necessitates a greater reliance on electricity. Therefore, it is imperative that those who work within and/or parallel to the electrical industry, be they electricians, engineers, maintenance professionals, etc, know how to ensure electrical safety. More so, that workforces understand the importance of electrical safety; appreciate the risks of compromising safety procedures; and are actively encouraged to implement stringent safety standards.

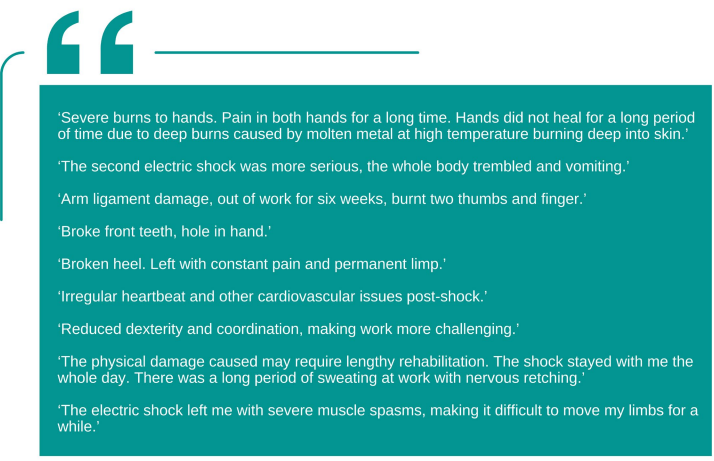

ETT’s Electric Shock Survey is important because it identifies key information such as electric shock frequency, causes, and reports. Subsequently, it uses this data to establish the electrical/trade industry's attitude to these accidents. From this, the report identifies areas for improvement. These recommendations are critical because, as the ETT report highlights, it takes very little current to damage the human body. Electric shocks, depending on their duration, voltage, and current pathways, can result in muscle spasms, burns, loss of consciousness, cardiac arrest, or respiratory failure. Indeed, those surveyed described a range of harrowing injuries sustained due to electric shock.

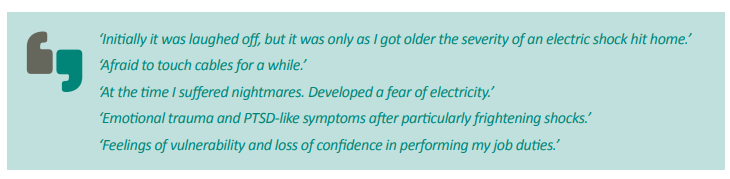

The impacts of electric shocks do not stop at physical injury. Many electrical professionals surveyed detailed the lingering mental impacts of these incidents.

Electric Shock Survey Respondents

342 electrical workers responded to ETT’s Electric Shock Survey. These respondents were drawn from Northern Ireland’s eleven government jurisdictions with a majority describing themselves as electricians (35%) or electrical apprentices (22%). The survey was disseminated to electrical workers of all experiences; however, most respondents had been in the industry for fifteen years or more (53%).

Electric Shock Survey Main Findings

The most astonishing finding of the Electric Shock Survey is that 80% of respondents have experienced an electric shock at work and 40% have suffered three or more shocks throughout their career. These high percentages indicate failings within the electrical industry to protect staff. They also suggest that suffering an electrical shock at work has been culturally accepted as 'the norm', especially as respondents expressed that:

“ 'quick jabs’ and ‘small shocks’ are not very serious, and in many ways have come to be viewed as part of the job.”[2]

Physical & Mental Injuries

Of those who have sustained an electric shock, 89% developed an injury, while 95% had to take time off work. Injuries resulting from an electric shock included:

- Burns (46%)

- Pain (16%)

- Shock (7%)

Furthermore, 23% of respondents who had suffered an electric shock reported that they were more cautious as a result, whereas 9% disclosed that they felt anxious for some time after the incident.

Industry Attitude

Despite 59% of respondents insisting that they would always report an electric shock and seek medical help, only 26% attested to recording an incident. Worse still, 26% is likely an overestimation as the ETT report explains:

“[…] this survey [does] not factor the frequency of electric shock incidents versus the frequency of reporting i.e., an individual may have received 3+ shocks and reported only 1 of them, but would respond positively that ‘yes’ they have reported an electric shock to their employer. Therefore, it is expected the actual level of reporting may be lower than 26%.”[3]

There were three main reasons that electrical workers were reluctant to declare shocks to their employers.

1.) Company culture

Many respondents expressed a “fear of being punished” or a “fear of being perceived as incompetent, or feeling embarrassed”[4] as the main reasons for not reporting electric shocks. Others attributed not relaying incidents to one or more of the following:

- The unwillingness of colleagues/supervisors to complete reports

- Individuals and/or colleagues/supervisors not taking shocks seriously

- Believing electric shocks that have not resulted in physical injury do not need to be reported

2.) Ineffective Reporting Procedures

Overly convoluted and time-consuming reporting procedures combined with a lack of awareness of how to report shocks were some of the other reasons given for not registering incidents. Expanding on these reasons, respondents raised concerns about:

- A lack of training, awareness, and/or resources for conducting effective accident investigations

- Reporting occurrences not leading to any procedural changes or updates in corrective action

3.) Time Pressures

Pressures to meet project deadlines, and a perception that reporting electric shocks would “‘hold up the job’, or aggravate colleagues, or a client”[5], were also noted as reasons respondents did not declare accidents.

Electrical Safety Awareness

Almost all respondents (90%) agreed that there should be more electric shock prevention training and awareness-raising activities within the electrical/trades industries. This is despite 97% of those surveyed attesting that they had a good understanding of electric shock risks.

When pressed for suggestions on improving electrical safety awareness, the six most common responses were:

- More improved training delivered frequently (i.e. refresher training)

- Mandatory/certified electrical safety/electric shock prevention training

- Providing electric shock prevention training for both apprentices and experienced professionals

- Digital/online resources on electrical safety and electric shock prevention (e.g. videos)

- Frequent toolbox talks on electrical safety and electric shock prevention

- Electrical safety workshops, seminars, talks, and roadshows

Other suggestions included developing electrical safety/electric shock prevention training specifically for other trades working on site, as well as non-technical colleagues such as health and safety staff. The purpose of this is to increase the understanding of electric shock risks throughout the workforce; ensure all staff partake in and support the implementation of mitigation measures; and manage expectations to reduce time pressures on electrical professionals.

Electric Shock Causes

In addition to investigating electric shock frequency and the industry attitude to these incidents, the ETT Electric Shock Survey sought to establish the main sources of such accidents. It revealed there were seven common causes of electric shocks:

- Incorrect cable identification/labelling

- Not carrying out safe isolation/working live

- Inexperience (e.g. the incident occurred as an apprentice)

- Borrowed neutral

- Previous poor-quality work, faults, or damage

- Lack of care/concentration

- Back feed

Importance of Safe Isolation

ETT’s survey discovered that not carrying out safe isolation was the second most common cause of electric shocks. In fact, only 52% of respondents attested to following proper safety procedures, such as safe isolation, all the time; while 40% admitted to taking shortcuts that could lead to an electric shock. Of this 40%, nearly two-thirds (62%) confessed that time pressures were the most significant influence when it came to by-passing safety procedures; 27% said "it was impossible to follow the safety procedures"; while just under a quarter (24%) stated: “there was no isolation equipment available”.[6]

Despite this, when asked which safety measures were most important for preventing electric shocks, 68% of respondents identified safe isolation as the primary precaution. This was followed by 26% who said correct safety equipment; 22% who attested training and awareness; and 20% who asserted safety procedures were critical to preventing electric shocks.

In light of these findings, the ETT suggests the following actions to highlight the importance of safe isolation and, in so doing, reduce occurrences of electric shock:

- Increased and improved internal communication impressing the importance of safe isolation and not taking shortcuts

- Revising safety procedures to make them easier to follow and implement

- Ensuring safety equipment is affordable, accessible, and of adequate specification

- Destigmatise the use of lockout kits through improved education on the importance of safe isolation

- Standardise safety procedures including safe isolation

- Deliver frequent, high-quality, consistent, standardised training

- Provide all apprentices with a free lockout kit

- Standardise the specifications of safety equipment and tools

How Can PASS Help with Safe Isolation?

Fortunately, of all the causes of electric shocks, not carrying out safe isolation is perhaps the one that individuals are most empowered to correct (save possibly lack of concentration/care). PASS Ltd, as a leading provider of test equipment by some of the most well-renowned brands, is perfectly placed to help you ensure your and your colleagues’ safety.

We offer a comprehensive range of affordable safe isolation and lockout equipment, including carefully compiled safe isolation and lockout tagout kits that include everything you need to secure and safely “make dead” circuits under investigation. Our extensive selection includes kits and tools by reputable manufacturers such as DiLog, Fluke, Kewtech, Lockout Lock, Martindale, MasterLock, and Socket and See.

Safe Isolation Procedures

ETT recommends the standardisation of safety procedures including safe isolation; while we await an industry response, it may be helpful to use Martindale’s A.L.I.V.E safe isolation steps as a guide.

Stay A.L.I.V.E With Martindale’s Safe Isolation Steps

Additionally, if you wish to refresh your knowledge of industry regulations, consider enrolling on one of our electrical training courses. We offer courses covering everything from PAT testing to 18th Edition updates to safe isolation.

Enrol On a Safe Isolation Course

Browse Our Electrical Training Courses

Further Information

For additional advice regarding safe isolation and lockout tagout procedures or for help choosing an appropriate kit, please get in touch with our Sales team on 01642 931 329 or via our online form.

Alternatively, please contact our training team on 01642 053512 or via our enquiry form for information regarding training courses.

Sign Up for Safe Isolation Course

In the meantime, please consult our blog for further guidance regarding safe isolation.

Safe Isolation Staying A.L.I.V.E

[1] All statistics, information, & quotes have been gathered from the following source:

- ETT, Ending ‘Shock Silence’ Creating A Safer Future For The Electrical Industry (Northern Ireland: Electrical Training (NI) Ltd, 2024)

A copy of the report can be requested by emailing info@ett-ni.org

An overview of the report may be found here.

[2] ETT, Ending ‘Shock Silence’ Creating A Safer Future For The Electrical Industry, p.11.

[3] ETT, Ending ‘Shock Silence’ Creating A Safer Future For The Electrical Industry, p.20.

[4] ETT, Ending ‘Shock Silence’ Creating A Safer Future For The Electrical Industry, p.21.

[5] ETT, Ending ‘Shock Silence’ Creating A Safer Future For The Electrical Industry, p.21.

[6] ETT, Ending ‘Shock Silence’ Creating A Safer Future For The Electrical Industry, p.24.