Please note this blog was originally published in July 2012. It was updated on the 30th April 2021.

Through its technological advances, the modern world has brought us a lot of new materials, substances, and other goods to make our lives easier, better, and a lot more comfortable.

Electricity is one of the most common and most relied upon of the modern inventions; it is, however, still one of the most dangerous if it is misused or its applications of use are underestimated.

Quick Links

- What is Insulation & Why Do We Need it?

- Insulation Degradation

- Monitoring Insulation Resistance

- PAT Testing & Insulation Resistance

- Further Information

What is Insulation & Why Do We Need It?

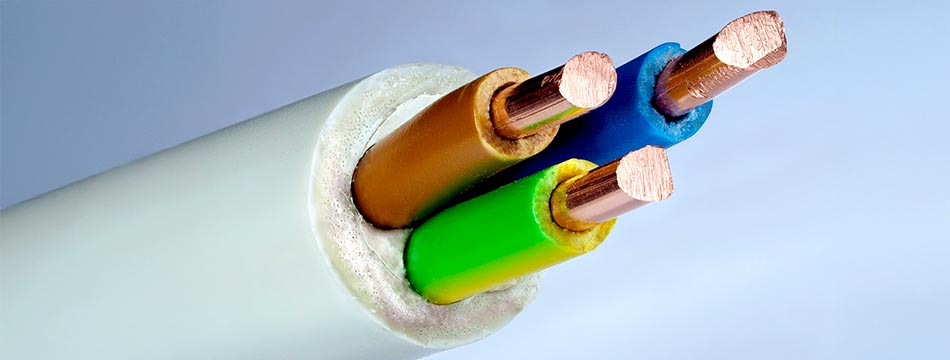

Any item that carries an electrical current is designed to do so safely and with some type of insulation. The insulation limits the flow of current between the different conductors and between the conductors to ground. It is therefore very important that the insulation has the opposite transfer properties of the conductor.

Conductors are usually metallic. The most common are copper or aluminium, both of which are known to be very good conductors of electric current due to the metals’ high current carrying capacity and constant thermal properties.

Insulation is usually made from a non-metallic material. The majority of electrical insulation is made of PVC, plastic, or rubber. It should resist current and keep it within the path alongside the conductor. Many of the best insulators are man-made.

In theory, insulation should not carry electrical current. However, in reality, there isn't a perfect insulating material. Every kind of insulation offers resistance; usually, the material's resistance is very high, however, it is not infinite. Obviously, the higher the resistance, the better the insulation capacity the material has.

Insulation Degradation

Manufacturers of wires, cables, and motors have continually improved their insulation. For areas where electricity is being used in industry (and in the home), manufacturers have repeatedly and successfully developed better products at lower costs. However, while in use, insulation is subject to many effects which can cause it to fail: mechanical damage, vibration, excessive heat or cold, dirt, oil, corrosive vapours, moisture from the air, and general wear and tear.

A combination of electrical stress and the degradation of insulation is constantly happening. One of the major causes of insulation failure is general wear and tear. As pinholes or cracks develop, moisture and foreign materials penetrate the insulation, providing a lower resistance path for leakage current. Once started, different degradation processes aid each other; this will then permit excessive current through the insulation.

Monitoring Insulation Resistance

Leaking current cannot be detected by smell or by sight. This is what makes it so dangerous as only the consequences can be noticed - often too late.

Having a planned maintenance program in place makes it more likely that gradual reductions in insulation resistance will be detected. Defective parts can then be repaired or replaced before full field failure occurs. If a maintenance program is not in place then items with poor or degraded insulation may become dangerous to touch when voltage is applied. Moreover, badly insulated items may become hazards to both the user and any person in the immediate area.

A sudden drop in insulation resistance is very rare; the most common cause of this is when a device has been subject to complete submersion. Therefore, monitoring gradual drops in resistance as part of a regular insulation resistance testing program is vital to limiting the risk of electric shocks, maintaining the safety of personnel, and reducing repair times due to failure. Detecting the onset of insulation breakdown means scheduled maintenance programs can be implemented. These may include one or more of the following steps: in-depth cleaning, renewal, drying, and/or rewinding. Measuring/ monitoring insulation resistance can also be helpful when evaluating the quality of repairs before equipment is put back into operation.

PAT Testing & Insulation Resistance

The normal steps for a Class 1 PAT test include visual checks, as well as earth bond, insulation resistance, (occasionally) flash, and leakage tests. For a Class 2 test, the sequence is visual, insulation resistance, (occasionally) flash, and leakage. Any checks that result in a fail should stop the test; the item-under-investigation must not be returned to general use.

Insulation resistance tests are always carried out as either the first or the second powered test according to the order of electrical safety. All mainstream PAT testing equipment supports insulation resistance tests, commonly known as DCIR. They are conducted using a DC test voltage which can range from 250V to 500V up to 1000V. The voltage is applied through the live-neutral connections and is measured against the earth. The higher the reading the better: for a Class 1 appliance, the reading must be above 1M Ohm, while for a Class 2 appliance it must be above 2M Ohm.

Further Information

Please browse our eclectic range of PAT testers and PAT testing equipment by leading brands, such as Seaward, Fluke, Kewtech, Martindale, and Metrel, here. For more information regarding any of our products, please contact our Sales team on 01642 931 329 or via our online form.