It is integral that gas engineers invest in a flue gas analyser (FGA), sometimes referred to as a combustion analyser, they can rely on, i.e., one that suits their purposes. As such, there are several criteria that plumbers and engineers should compare before making their choice. Of course, these key features include budget and sensor type; however, it’s also important to contemplate your preferred reporting method, as well as your calibration requirements. This guide outlines the specifications you should pay attention to when selecting a flue gas analyser for your application.

Quick links:

- What kind of application will you be using your flue gas analyser for?

- What is your flue gas analyser budget?

- Which gasses are you testing?

- Which fuel types will you be testing?

- Do you need additional measurements?

- How do you want to view & report results?

- What kind of sampling probe is best?

- Should I upgrade to a flue gas analyser kit?

- Which flue gas analyser calibration service works best for you?

- What other FGA features should I look for?

- Popular Flue Gas Analysers

- Further Information

1. What kind application will you be using your flue gas analyser for?

Before you can set a budget; specify sensors; or assess additional features, you must first establish your application type, as this will inform all subsequent criteria. Below the three main sorts of applications, domestic, commercial, and industrial, are outlined. Your work may involve a mix of two or all three, so always bear in mind your most demanding application when comparing analysers.

Domestic Applications

Domestic applications usually encompass checking, servicing, and troubleshooting boilers and gas appliances in private or rented homes. This means domestic gas engineers will probably encounter combi, system, conventional, condensing, or back boilers, and should select a combustion analyser capable of testing these appliances.

Shop Flue Gas Analysers for Domestic ApplicationsCommercial Applications

Servicing, checking, and troubleshooting boilers and gas appliances in non-residential buildings, for example, offices or warehouses, are considered commercial applications. Gas engineers engaged in commercial work may come across combi, system, conventional, condensing, and energy-efficient boilers. As such, they should choose a flue gas analyser suitable for use on these appliances.

Moreover, given that commercial boilers have higher output capacities than domestic boilers, engineers and plumbers should select a combustion analyser with sensors suitable for measuring and withstanding greater gas concentrations.

Shop Flue Gas Analysers for Commercial ApplicationsIndustrial Applications

Advanced flue gas analysis involved in the commissioning, servicing, troubleshooting, and optimisation of industrial burners, stationary industrial engines, gas turbines, and flue gas purification systems all fall under the remit of industrial applications. Additional tasks could include:

- Control and monitoring of prescribed emission limits in exhaust gas

- Function testing of stationary emission measuring instruments

- Control and monitoring of prescribed gas atmospheres in furnace rooms

Consequently, industrial plumbers and gas engineers will want a combustion analyser adept at analysing emissions from these systems without sustaining damage. Furthermore, industrial applications often involve checking the concentrations of multiple gases. As such, your chosen FGA must have the capacity to hold several sensors.

Shop Flue Gas Analysers for Industrial Applications2. What is your flue gas analyser budget?

Allocated funds will always have a commanding influence over any purchase, business or otherwise. At PASS Ltd, we understand that. That’s why we stock an eclectic selection of top-brand flue gas analysers and FGA kits at a range of price points. From entry models to midrange and flagship analysers, we ensure you do not have to compromise quality when accommodating your budget.

Shop flue gas analysers by price:

To guarantee you choose an analyser that meets your measuring and functionality obligations without outstripping your funds, always bear your budget in mind when evaluating the following criteria.

3. Which gasses are you testing?

Shop flue gas analysers by gas sensor:

- CO - Carbon Monoxide

- O2 - Oxygen

- CO2 - Carbon Dioxide

- NO - Nitric Oxide

- NO2 - Nitric Dioxide

- HC - Hydrocarbons

- SO2 - Sulphur Dioxide

- H2S - Hydrogen Sulphide

- CO(H2) - Carbon Monoxide (Hydrogen Compensated)

Domestic Boiler/System Gasses

As a domestic gas engineer, you need to measure oxygen (O2), carbon monoxide (CO), and carbon dioxide (CO2). Most flue gas analysers are fitted with electrochemical oxygen and carbon monoxide sensors and use data gathered by these components to calculate CO2. However, purchasing a combustion analyser with a CO2 sensor is possible. This will enable you to measure ambient carbon dioxide, although it will increase the cost of your FGA. Therefore, mull over whether you want a real-world reading or if a calculated value will be sufficient.

Additionally, take into account the upper limit of your carbon monoxide sensor. Most FGAs optimised for domestic applications have a 4000 ppm CO sensor complemented by a pump shut-off which will activate if the CO maximum is reached. Combustion analysers are designed this way to prevent sensor damage caused by CO spikes or excessive exposure to carbon monoxide. Judge carefully whether this maximum is fit for your purposes. If you believe you may experience CO spikes greater than 4000 ppm, it may be worth investing in a long-life flue gas analyser or one that can endure higher carbon monoxide levels. This will mitigate damage to your analyser and, despite a greater initial investment, will save you money on calibration and repair bills in the future.

However, if you are contemplating a combustion analyser with a higher CO tolerance, it may be worth rethinking your application. Do you need an FGA suitable for commercial or industrial applications?

Shop Flue Gas Analysers for Domestic ApplicationsCommercial Boiler/System Gasses

In addition to oxygen (O2) and carbon monoxide (CO), commercial gas engineers/plumbers may elect to include a carbon dioxide (CO2) sensor. Nevertheless, before opting for a model with this component, remember that most commercial flue gas analysis necessitates the measurement of nitrogen oxides (NOx gases): that is nitric oxide (NO) and nitrogen dioxide (NO2). Some flue gas analysers can only accommodate three gas sensors. Therefore, reflect on whether you wish to determine a real-world CO2 concentration or if a calculated value will suffice. If you do need a flue gas analyser with four sensors, be aware this will probably incur an additional cost.

Furthermore, as previously mentioned commercial boilers have higher output capacities than typical domestic boilers; consequently, combustion analysers must be able to weather and measure greater concentrations of CO. Some models feature CO sensors with ranges up to 30 000ppm, accompanied by an effective dilution system that prevents damage and extends the sensors’ longevity.

Shop Flue Gas Analysers for Commercial ApplicationsIndustrial Boiler/System Gasses

As with commercial combustion analysers, flue gas analysers for industrial gas equipment must be capable of surviving and registering high gas concentrations. Moreover, as industrial applications usually involve measuring multiple gases, ensure you invest in a model with the capacity to hold several sensors. Consider which gases you will encounter; as industrial flue gas analysers may be fitted with your choice of the following:

- Carbon Monoxide (CO)

- Low Range Carbon Monoxide (COlow)

- Oxygen (O2)

- Carbon Dioxide (CO2)

- Nitric Oxide (NO)

- Low Range Nitric Oxide (NOlow)

- Nitrogen Dioxide (NO2)

- Sulphur Dioxide (SO2)

- Hydrogen Sulphide (H2S)

- Hydrocarbons (CxHy)

Please contact our Sales team on 01642 931 329 or via our online form for advice regarding any particular gas or gases.

Shop Flue Gas Analysers for Industrial ApplicationsVentilation System Gasses

Flue gas analysers employed in assessing indoor air quality (IAQ) or ventilation systems are primarily concerned with measuring CO. This is because carbon monoxide build-up will compromise air quality and, therefore, human and animal safety. This gas result from incomplete combustion Therefore, if you anticipate using your flue gas analyser for IAQ or ventilation applications, ensure you purchase an FGA fitted with CO, CO₂, O₂, and NOx sensors, as these are is essential for assessing combustion efficiency and detecting hazardous emissions.

Shop Flue Gas Analysers for Ventilation & IAQ ApplicationsEngine & Air Conditioning Gasses

Flue gas analysers used to ensure efficient engine performance and air conditioning (A/C) integrity must be able to measure exhaust emissions and refrigerant functions accurately and reliably. As such, if you intend to use you combustion analyser for these purposes, you'll need to invest in an FGA that can determine CO, CO₂, O₂, NOx, and hydrocarbons concentrations in line with relevant standards.

Shop Flue Gas Analysers for Engine & A/C Applications

Please call our team on 01642 931329 or contact us via our online form for advice regarding any particular gas or gases.

4. Which fuel types will you be testing?

You must invest in a flue gas analyser compatible with the fuel types you are qualified to test and will work with when checking and servicing gas appliances.

Most UK gas engineers are qualified to work on the following fuels as they are commonly used in Britain and Northern Ireland:

- Natural Gas (Methane, CH4): supplied through the mains gas network, Methane is widely used for heating and cooking in UK homes, as well as powering commercial and industrial boilers.

- LPG (Liquefied Petroleum Gas): comprised of propane (C3H8) and butane (C4H10) stored in tanks or cylinders, LPG is a common alternative for heating and cooking in homes not connected to the UK’s main gas network. It is mostly used in rural areas.

- Oil: some off-grid homes use oil to fuel boilers and heating systems, though not gas, engineers may have to test/service appliances powered by oil, particularly those involved in checking commercial and industrial boilers.

- Biogas: derived from organic waste, BioGas is a renewable alternative to natural gas. As such, some gas engineers may come across boilers or systems fuelled by BioGas.

- Other: Coke, Coal, Wood pellets, Bagasse

Assess carefully, first, whether you are qualified to work with these fuels and, second, if you are likely to encounter them in your day-to-day operations. Compatibility with more fuel types can affect the price of combustion analysers.

5. Do you need additional measurements?

Often, to check/service boilers and other gas appliances comprehensively extra tests are necessary. When choosing a flue gas analyser, keep in mind whether you’ll have to measure pressure, temperature, and/or tightness, as well as calculate CO: CO2 ratio, excess air, and/or combustion efficiency.

Shop flue gas analysers by popular measurements:

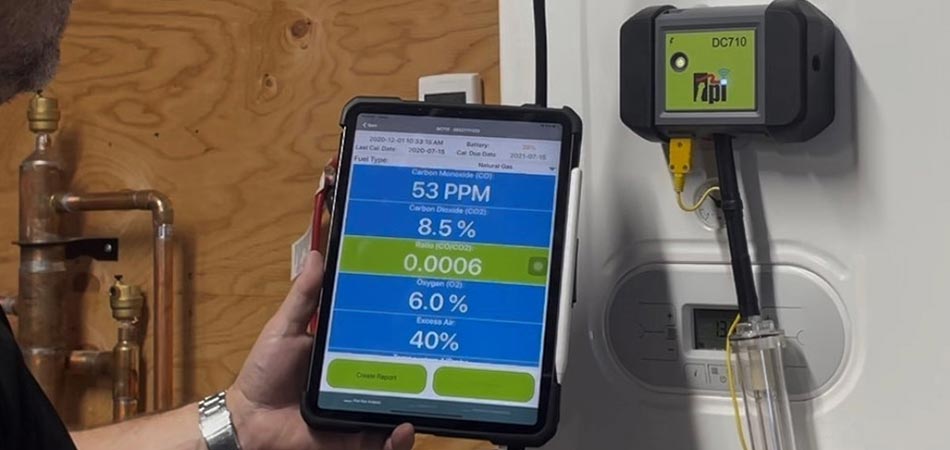

6. How do you want to view & report results?

Fear not, you don’t have to be a tech bro from Silicon Valley to answer this question. Just decide whether you would like to operate your flue gas analyser directly; using an app and smartphone/tablet; or both. Similarly, think about where you would like to save data. Do you want an analyser with an inbuilt memory or would you rather save measurements to an app or Cloud space?

Do you want a display?

Ridiculous as this question may seem, you might find that you do not need a display. If you anticipate installing your FGA in awkward-to-reach locations, meaning you will be unable to see the screen, perhaps a screenless flue gas analyser operated remotely using an app and smartphone/tablet would be preferable.

Nevertheless, you might prefer not to rely on an app and Bluetooth connectivity. In this case, you will want a model with a display. All leading brands, including Anton, Kane, Sauermann, Testo, and TPI have entry, mid, and flagship models with displays. Many of these models also include app connectivity, providing greater operational flexibility. Readings may be taken directly from the analyser; although, if this is not possible because, for example, the unit is installed in an area or position that blocks access to the screen, you can still record data and conduct tests remotely via an app and a smartphone/tablet. Consequently, you can maximise your productivity while making testing easier.

How would you like to store & export data & reports?

- Internal memory: most models log data to an internal memory. These measurements may be exported to a laptop or PC to create reports.

- Printers: some flue gas analysers interface with a printer, allowing you to generate reports onsite.

- Cloud storage: combustion analysers compatible with a dedicated app will sync data to a specific platform and/or Cloud, allowing you to create and send reports (via email) on-site.

Printer and app-compatible models reduce reporting time and enable you to complete each job on location before moving on to the next, once again, maximising productivity.

Shop Flue Gas Analysers with App Connectivity7. Which kind of sampling probe is best for your application?

Generally, domestic gas engineers use a 180mm x 6mm probe that can measure up to 500°C. However, commercial/industrial gas engineers/plumbers may like a longer or wider probe able to endure higher temperatures. Moreover, probes with modular designs are often preferable when working with commercial/industrial boilers as they can be adapted to accommodate the unit.

Always consider the temperature, pressure, and corrosiveness of the gases you will be sampling and select a probe tolerant of all these factors. Furthermore, bear in mind the types of flues you may encounter. If you work with large gas appliances or appliances with a raised flue, you might want to invest in a longer sampling probe. Similarly, if you anticipate checking and servicing boilers or gas appliances in confined spaces, a flexible sampling probe, or one offering an angled design, could make accessing these flues easier. Most combustion analysers can be used interchangeably with different sampling probes of the same brand (e.g. Testo FGAs can be used interchangeably with Testo sampling probes).

Shop Flue Gas Probes8. Should I upgrade to a flue gas analyser kit?

Whether you should upgrade to a kit or not will depend on your budget, existing aresenol of tools, and intended application. You might be constricted by your budget or already own an array of gas accessories/probes, in which case it may make more financial sense to invest in a standalone unit. However, if you need a flue gas analyser for a specific application or require the added measurement capabilites available with additional accessories, buying a flue gas analyser kit may be a cost-effective option.

Flue gas analyser kits come in various configurations, designed to meet the specific needs of the systems being tested. As such, they include diverse combinations of tools that complement or expand the FGA's capabilities. Additional insturments included in a combustion analyser kit may include:

- Printer: enables immediate on-site paper-based reporting

- Temperature clamps and air/liquid temperature probes: provide precse measurements of air/liquid temperatures, facilitating accurate system checks

- CO alarms: detect hazardous carbon monoxide levels

- Gas leak detectors: ensures there are no leaks in the system

- BS7967/CPA1 probe: samples fumes from flueless appliances such as cookers and grills, allowing you to check their gas safety

- Oil kit and smoke pump: facilitates the testing of oil-fired systems, including pressure measurement and smoke level analysis

- Manometers: enables let-by and tighness testing

- Digital manifold: kits with a digital manifold help to future-proof your business as these instruments can be used to check heat pumps; however, sets with both an FGA and manifold tend to be the most expensive

Shop flue gas analysers by kit contents:

- Printer

- Gas Leak Detector

- BS7967 / CPA1 Probe

- Temperature Clamps

- Air / Liquid Temperature Probe

- Oil Kit & Smoke Pump

- Heat Pump Manifold

- CO Alarm

- Manometer

9. Which flue gas analyser calibration service works best for you?

To ensure accuracy and reliability, flue gas analysers must be calibrated annually. To help you maintain compliance, many models provide calibration reminders and some will lock you out until a calibration is performed.

All brands will calibrate your combustion analyser in-house. However, sending your analyser away for calibration, especially if your chosen brand’s laboratories are far from your location, can be time-consuming, leading to prolonged downtime and significant loss of earnings. Moreover, brands that insist on customers returning units to their labs, whether they were purchased directly from them or via a distributor, often end up with a calibration backlog, resulting in weeks of delays, ultimately costing you economically and reputationally.

Many leading brands understand the issues with insisting on in-house calibration; yet, they also appreciate that customers want to be certain their FGA has been calibrated correctly per the manufacturer’s guidelines. That’s why these brands have certified various calibration labs across the UK as approved service centres. Sending your flue gas analyser to one of these locations, you can be sure it will be calibrated to exacting, manufacturer-approved standards, guaranteeing you peace of mind while allowing brands to avoid unnecessary backlogs. It also offers customers the opportunity to select a centre closer to their location, providing the option of dropping off and picking up their unit at a time that is convenient to them.

When choosing an analyser, weigh up your calibration preferences and especially how much flexibility you want. Brands such as Kane, which insist on calibrating all Kane units, will deliver precise calibration and this may suit your work situation. Alternatively, if you want access to an approved service centre in your area that will guarantee manufacturer-approved precision, a different brand of flue gas analyser (e.g. Anton, Testo, or TPI) may serve you more effectively.

About Flue Gas Analyser CalibrationPASS LTD is an approved gas calibration services centre for Anton, Testo, and TPI, get in touch for a quote.

10. What other FGA features should I look for?

In addition to the aforementioned criteria, other factors to compare when choosing a combustion analyser include ease of use and battery life.

Ease of use

Is your chosen flue gas analyser intuitive and, if you plan on using it alongside other testers, does it integrate seamlessly into your existing tool ecosystem?

Battery life

It is important that your combustion analyser can keep up with your work schedule. Think about your average work day, how many hours do you usually spend testing? Then ponder your chosen FGA, will its battery life meet these demands and how quickly can it be recharged?

Popular Flue Gas Analysers

Further Information

For more help or advice on choosing the correct combustion analyser for your requirements, please don’t hesitate to call our Sales team on 01642 931329 or contact us via our online form.

In the meantime, please browse our extensive range of flue gas analysers.